Borgeson and X-Cart Q&A: Auto Parts Manufacturer’s Road from Production to Online Sales

We recently visited the facilities of Borgeson Universal Co., Inc, a leading manufacturer of automotive steering components. What we found was a highly automated, vertically integrated operation that quietly turns raw steel into thousands of precision parts every day.

This visit wasn’t just about machines and metal. It was about understanding how a manufacturer like Borgeson aligns production, inventory, and eCommerce to support growth.

In this shop-floor Q&A, Brandon Checketts, CEO of X-Cart, and Jordan Checketts, COO of X-Cart, walk the facility with Jeff Grantmeyer and the Borgeson team, asking practical questions manufacturers care about – automation, scale, inventory, and sales.

Along the way, we highlight how X-Cart provides the eCommerce engine that connects Borgeson’s manufacturing efficiency directly to online revenue.

1. Automation as the Second Shift

Standing next to rows of CNC machines running overnight, the scale of Borgeson’s automation becomes immediately clear.

Your automation level is impressive – to be able to run this many machines and produce this volume with only 25 people. What did staffing look like back when everything was manual?

We peaked at about 55 employees when we were probably one-tenth the size we are now in sales. Back then, everything was manual. We’ve continuously automated ever since. We could run a second shift if we needed to – but these machines are the second shift.

Insight for Manufacturers

Automation doesn’t just increase output – it changes how you scale. Borgeson can grow production without increasing headcount, removing a common bottleneck many manufacturers face.

How X-Cart Fits In

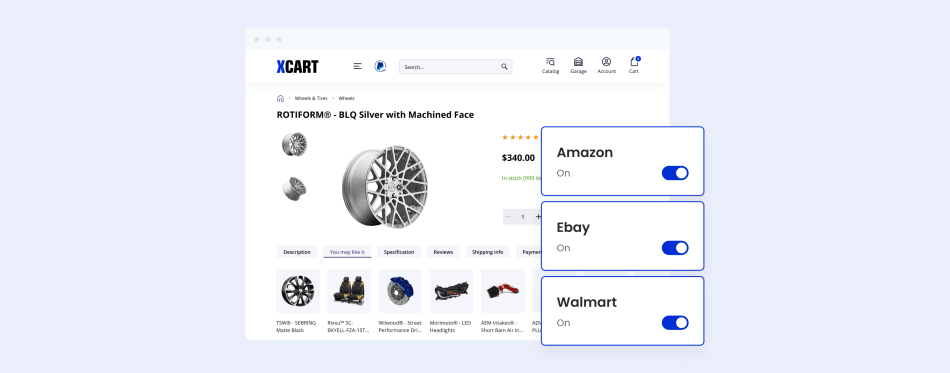

Borgeson’s production is nearly a closed loop from 12-foot steel bars to finished parts running overnight. X-Cart mirrors that efficiency on the sales side:

- ERP and inventory management system;

- Real-time stock updates across 12,000+ SKUs.

2. Maximizing Raw Material and Volume Sales

Walking past stacks of raw material, Jordan points out something many industries never deal with.

Not too many industries have to justify a truckload based on weight instead of volume. So if you buy direct from a steel mill, you can get better pricing, and the best price you can get is to load a truck… You’ve just maximized your efficiency there.

We didn’t always do that. During the pandemic, supply chains became unpredictable, so we increased our purchase volumes and haven’t gone back. We’re going to use the material. It doesn’t go bad; it doesn’t have a shelf life.

Insight for Manufacturers

Bulk purchasing improves margins, but only if you can move finished products efficiently.

How X-Cart Fits In

When you’re investing in 50,000-pound truckloads of steel, your eCommerce platform has to support volume sales:

- Tiered pricing for distributors buying in bulk;

- B2B functionality that matches manufacturing scale with sales incentives.

This allows Borgeson to monetize bulk inventory instead of letting it sit.

3. Managing a Massive Catalog Without Slowing Down

As the tour continues, it becomes clear how much product variety Borgeson manages on a daily basis.

With over 12,000 SKUs, how much time goes into deciding what new products to build?

Customers take care of that. They tell us what they need and what they keep asking for. That guides what we develop.

Insight for Manufacturers

Large catalogs don’t have to create complexity if your data is structured properly.

How X-Cart Fits In

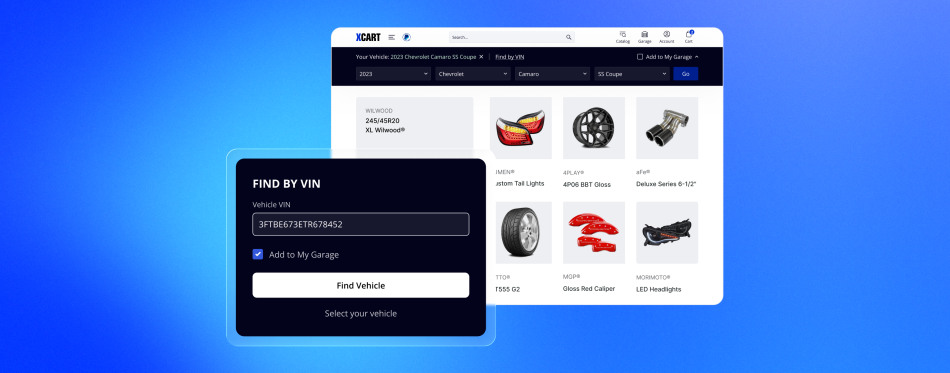

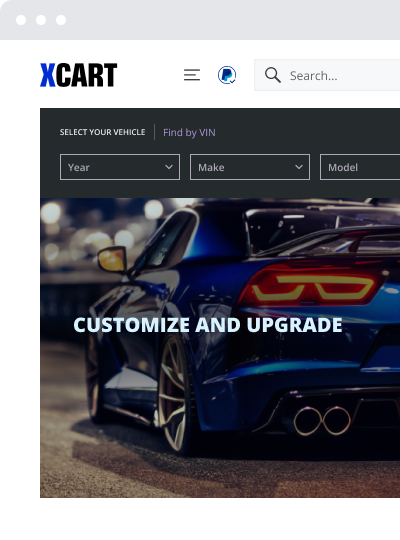

For automotive manufacturers, selling parts in bulk or D2C, fitment accuracy is non-negotiable:

- Year/ Make/Model (YMM) filtering narrows thousands of parts down to the exact match

- Product Information Management (PIM) stores critical specifications such as spline count, bore diameter, and materials.

The result: customers find the right part faster, with fewer errors.

4. Precision in Assembly and Fulfillment

Near the end of the tour, manufactured parts move seamlessly toward packaging and shipping.

You’ve got dedicated stations for each assembly step – how does that flow into fulfillment?

Once parts are packed, they go on the belt, pass invoicing, and move straight out the door.

Insight for Manufacturers

A fast assembly line means nothing if fulfillment slows orders down.

How X-Cart Fits In

Shipping Integrations: The platform automatically calculates shipping costs and generates shipping labels, ready to meet the packaged parts as they come down the conveyor belt. This ensures the sales speed matches the assembly speed.

Why This Matters for Auto Parts Manufacturers Selling Online

Borgeson is a clear example of what happens when manufacturing discipline meets the right digital infrastructure. Their operation is refined, automated, and data-driven, so their eCommerce platform has to be as well.

X-Cart provides a scalable, B2B-ready, inventory-integrated eCommerce solution that allows manufacturers like Borgeson to:

- Turn raw material into sellable inventory faster.

- Keep massive catalogs searchable and accurate.

- Align production speed with online sales and fulfillment.

For manufacturers transitioning to or scaling eCommerce, Borgeson’s approach offers a practical blueprint: Automate where it matters, structure your data, and connect production directly to sales.

Need similar results for your automotive eCommerce?

About the author