8 Order Fulfillment Best Practices for the Automotive Aftermarket

When you think about optimizing order fulfillment, you might imagine finding more efficient picking, packing, and shipping strategies. But fulfillment is about more than just efficiency. It’s about meeting and managing growing customer expectations at every stage of the delivery process.

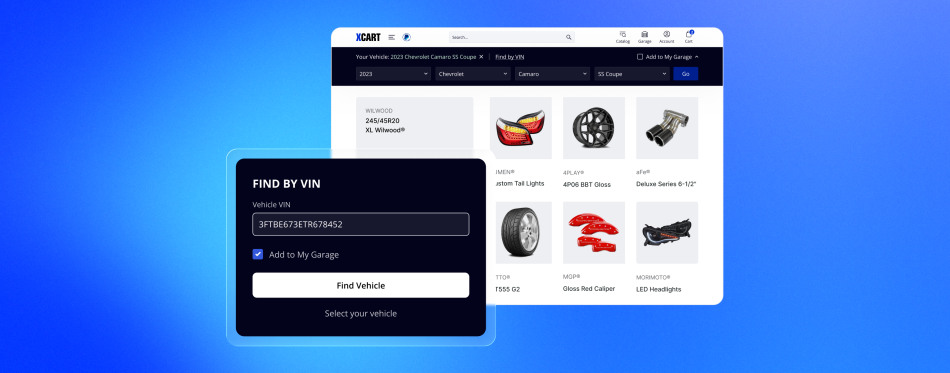

Automotive aftermarket sellers face unique complexity: large catalogs with complex fitment data (year, make, model, engine type, bolt patterns, etc.), multiple fulfillment locations, and products ranging from fragile sensors to heavy bumpers. Creating consistent, reliable delivery experiences is a challenge, but it’s worth it if you want customers to never return what they’ve bought.

Building a Return Fulfillment Process That Drives Loyalty

Good eСommerce order fulfillment needs three things: smart planning, the right technology, and happy customers. In reality, even the best-run operations face issues like package delays, part mispicks (often due to fitment confusion), and underperforming carriers that frustrate customers. What separates successful aftermarket brands from competitors is how smoothly they navigate these challenges.

How do you go from a brand that simply delivers to one that inspires loyalty through fulfillment? We’ll help you transform your fulfillment from functional to loyalty-building with these eight practices for the automotive aftermarket.

1. Design eCommerce Order Fulfillment Workflows That Work When Things Go Wrong

The first step in creating a fulfillment process that drives loyalty is designing workflows that keep you on track even when things go wrong.

For aftermarket sellers, that might mean planning for inventory spread across multiple warehouses or supplier networks, or accounting for carrier restrictions on hazardous materials, like batteries or aerosols, or heavy parts.

Use these strategies to handle issues smoothly when they arise:

- Create backup processes before you need them. Don’t wait for a carrier strike or system outage to design contingencies. Build workflows that allow you to reroute orders between fulfillment locations or switch carriers quickly when needed.

- Focus on escalation procedures. Document exactly what happens when an order fails, who gets notified, who has the authority to respond, and how you keep customers updated.

- Plan for multiple scenarios. Include playbooks for incorrect addresses, carrier disruptions, and international customs holds, which are common when shipping auto parts across borders.

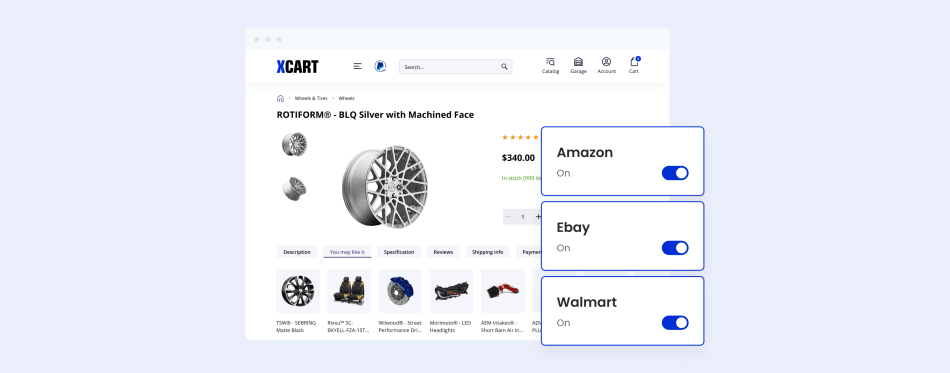

Platforms like ShipStation diversify carrier options, automate fulfillment workflows, and make it easier to manage multi-location or multi-channel shipping from your X-Cart store to eBay Motors and Amazon. This gives your team more time to focus on customer experience.

2. Give Your Team Authority to Solve Problems

Customer trust is won or lost in small moments of friction, especially when a shipment contains critical components that keep vehicles running for a repair shop waiting on a part to finish a job. Empower frontline staff to make quick decisions, such as authorizing replacements for damaged items or rerouting urgent orders without manager approval.

This autonomy ensures faster resolutions and happier customers, keeping them loyal to your brand instead of sending them to competitors.

3. Communicate Proactively, Not Reactively

You don’t need to offer two-day shipping to be competitive, but you do need to set clear expectations. Let customers know lead times for backordered parts or specialty/custom-painted items upfront, and provide transparent shipping estimates for each carrier option at checkout.

When delays occur, reach out first. Proactive communication, especially for high-value or time-sensitive auto parts, builds trust and reduces support tickets.

4. Make Returns and Exchanges Effortless

Returns in the automotive aftermarket can be complex, particularly when items are heavy, fragile, or incompatible with certain models — a constant challenge given the complexity of year, make, model fitment data. Streamlining this process builds confidence and repeat purchases.

Offer:

- Self-service return portals where customers can print labels or initiate exchanges instantly.

- QR code drop-offs for printerless returns.

- Prepaid return labels for peace of mind.

- Exchange incentives such as discounts for swapping items instead of returning outright.

Analyze return data to identify patterns like mis-shipped parts or frequent compatibility issues, then address them upstream in your order management process.

5. Optimize for Your Product Mix with Scalable Fulfillment Services

Auto parts vary drastically in size and fragility. Your packaging, storage, and carrier choices should reflect that diversity.

For example:

- Batch small-item orders like filters or brake pads for faster pick-and-pack efficiency.

- Set up dedicated workstations for oversized or irregularly shaped items, such as bumpers or exhaust pipes, to ensure safe handling.

- Automate routing to choose the most cost-effective carrier based on package size and delivery zone.

Automatically assign the best carrier service for each order type, simplifying fulfillment even as your SKU count and channels expand. ShipStation handles this routing for you.

6. Be Clear About Costs in Every Transaction

Surprise fees drive away customers, especially on large or international shipments of parts. Transparency at checkout should include shipping costs, duties, and taxes so buyers never face unexpected bills later.

For cross-border automotive sales, consider displaying total landed cost (product, shipping, and duty) at checkout. This clarity builds credibility and reduces abandoned carts.

7. Create Scalable Order Fulfillment Systems That Maintain Quality

As your aftermarket business grows, what works for 100 orders a day might not work for 1,000. Automate repetitive tasks like label creation or carrier selection, and integrate your order fulfillment system with your ERP or inventory management tools to maintain accuracy across channels.

Diversify your carriers to avoid disruptions and ship anything from small bolts to full exhaust systems without delay.

8. Turn Service Into Success

Every service interaction is a chance to reinforce trust. For auto parts sellers, this means following up after a replacement part ships or offering installation tips post-purchase, perhaps by linking to a PDF diagram.

Use fulfillment and support interactions as opportunities to strengthen customer relationships and drive repeat business. Even small gestures like a quick thank-you email with tracking updates can boost loyalty in a competitive market.

Turning Fulfillment Challenges Into Customer Wins

Great order fulfillment means fixing problems fast, not avoiding them. In the automotive aftermarket, where timing and precision are critical, every fulfilled order is an opportunity to prove reliability.

Use scalable technology, communicate early, and design workflows that reflect the unique challenges of multi-location, multi-channel auto parts shipping.

Automate workflows, consolidate carrier options, and maintain the flexibility to deliver exceptional fulfillment demands. ShipStation scales with your growth.

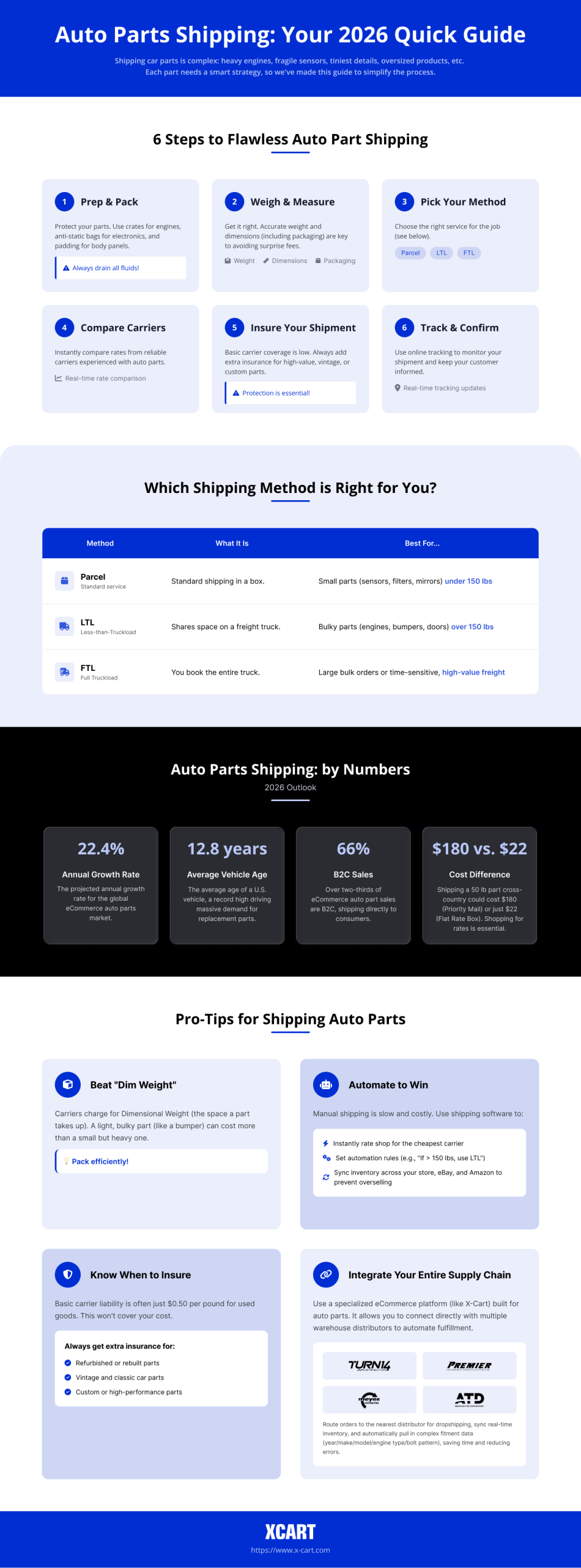

Bonus: Your 2026 Automotive Shipping Guide

About the author