Smart Order Routing and Fulfillment for Auto Parts eCommerce

Selling aftermarket auto parts online is not for the faint of heart. It is a tough business. Your customer is buying a complex part that needs to fit a specific year, make, and model. They are often in a hurry — their car is in the garage, perhaps on a lift. And the parts themselves? They range from a 2-ounce sensor to a 150-pound crate engine.

This complexity creates a massive backend challenge. How you get that specific part from a shelf to the customer’s doorstep is what separates the winners from the shuttered sales channels. This crucial workflow is built on order routing and fulfillment.

If your current order processing involves a human looking at online orders and guessing which warehouse to ship from, you have a problem. You are losing money on shipping costs and losing customers with slow delivery times.

It is time to talk about smart order routing, the automated brain of your eCommerce operation. A good order routing system is your single best tool to reduce shipping costs and meet modern customer demands.

What Is Order Routing?

Order routing (or routing) is a simple concept. It is the set of predefined rules your system uses to determine where an order should be fulfilled from.

In the old days, you had one warehouse. The order routing process was simple:

- Customer places an order.

- The order goes to your one fulfillment center.

- You pick, pack, and ship.

But the auto parts market is not simple. To compete, you need inventory in multiple fulfillment centers. You might have:

- An East Coast fulfillment center

- A West Coast fulfillment center

- A warehouse in the Midwest

- A dropship agreement with three major distributors

- A network of physical stores that can also ship parts

Suddenly, you have six or more multiple sources for the same part. When a customer in Nevada buys a brake caliper, where should it come from? Your California fulfillment center? Your distributor in Texas? This is the problem that smart order routing solves. It is an automated process that makes this decision for you in an instant.

This routing is the first, vital step. The order routing decision kicks off the whole order processing and fulfillment workflow, from assigning orders to the right location to having that location start processing the shipment.

Aftermarket Auto Parts: Unique Fulfillment Challenges

Why is a dedicated order routing system so critical for auto parts? Because this industry has multiple factors that make fulfillment a nightmare. A good routing process has to consider all of them.

1. Massive Inventory Complexity

You might stock (or have access to) millions of SKUs. Managing inventory levels for this endless aisle is a monumental task. A good order routing system must have real-time data about your available stock. It’s not enough to know you have the part; the system must know where that available inventory is located — right down to the specific fulfillment center or supplier warehouse.

This is the only way to prevent stockouts and avoid backorder emails that make a customer furious.

2. Extreme Shipping and Handling Costs

This is the big one. In auto parts, shipping costs can destroy your profit margin. You cannot have a simple, flat-rate shipping rule.

- Weight & size: A paper filter ships for a few dollars. A new bumper is an oversized item that requires a special shipping carrier.

- Special handling: Some parts, like batteries or certain fluids, require special handling and specific shipping carrier transports.

- Total cost: The total cost to fulfill an order includes the part, the box, the labor (handling costs), and the freight (transportation costs). An order routing decision must weigh all these costs.

Your order routing logic must be smart enough to know that shipping a 20-pound differential from your East Coast fulfillment center to a customer in California is a bad idea. The routing decision must prioritize the nearest distribution center that has the stock. This is the most direct way to reduce shipping costs.

3. High Customer Demands

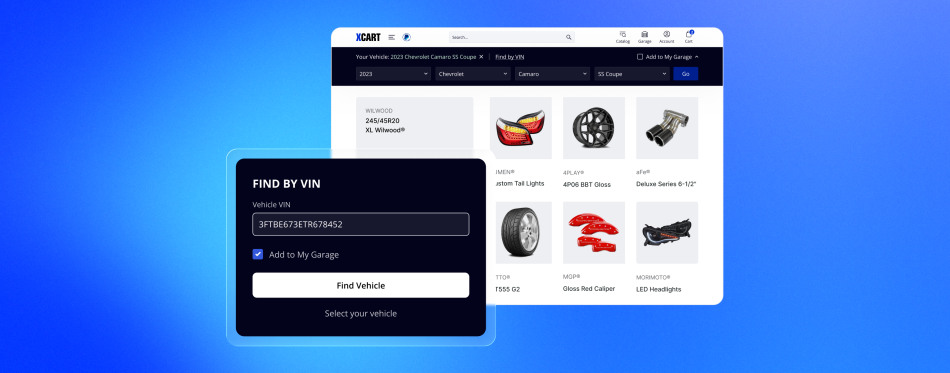

The auto parts customer needs speed. Urgent orders are the norm, as are returns for items that took too long to arrive or didn’t fit at all (80% of all eCommerce customers return their purchases). A mechanic cannot wait a week for a part; that is why delivery speed and short delivery times are a massive competitive edge. A smart order routing system makes this possible by:

- Instantly finding the nearest distribution center to the customer’s location.

- Checking inventory levels in real-time data to ensure the part is on the shelf.

- Routing the order to that fulfillment center immediately so they can start processing it.

The automated order routing cuts shipping time from five days to one, just by making a smarter choice at the moment the customer clicks Buy.

How Smart Order Routing Works

So, what makes an order routing system smart? It all comes down to routing rules.

These are if-then commands you set up in your automotive eCommerce platform. They create an automated process that analyzes every single order and sends it to the best possible order routes.

Let’s build a few examples of routing rules for an auto parts store.

Rule 1: Customer Location

This is the most common and powerful rule.

- IF a customer places an order…

- THEN the order routing system checks the customer’s location.

- AND it finds the nearest distribution center (or fulfillment center) with available stock.

- RESULT: The order is routed to that fulfillment center.

This is the basic rule, but it’s the foundation for low shipping costs and fast delivery speed.

Rule 2: Inventory Levels

But what if the nearest distribution center is low on stock?

- IF the customer’s location is in Zone A…

- AND the Zone A fulfillment center has < 5 units of the part…

- THEN the order routing system will route orders to the next closest fulfillment center (Zone B) that has > 50 units.

- RESULT: You fulfill the customer’s order from Zone B. This leaves the last few units in Zone A for other local, urgent orders, which helps prevent stockouts and improve service levels.

With this routing process, you use real-time data on inventory levels to make efficient shipping decisions.

Rule 3: Special Handling

Some parts are not normal.

- IF an order size is Oversized OR the item requires special handling (like a battery)…

- THEN the order routing system must route orders only to a fulfillment center that is equipped for freight or hazmat shipping.

- RESULT: You avoid assigning orders to a fulfillment center that cannot handle them, which prevents massive delays and costs. This defines the order routes.

Rule 4: Supplier Priority

Many stores use multiple sources, including dropship distributors.

- IF an order contains a part from Supplier X…

- THEN the order routing system can be told to always route orders for that part to your own fulfillment center first (if you have the stock).

- ELSE: If you are out of stock, the system automatically sends the order to Supplier X to fulfill.

- RESULT: You maintain control over your inventory and costs but have an automated backup plan. That is how you stabilize demand planning.

As you can see, the routing logic can get very complex. That is why you need a platform that can handle it and integrates with the latest shipping solutions. The smart order routing uses machine learning and predictive analytics to get better over time, finding the best order routes based on multiple factors.

X-Cart: Native Order Routing for Auto Parts

X-Cart is built with this complexity in mind – it is an order management and fulfillment engine.

Multi-Warehouse Distributor (Multi-WD) Functionality

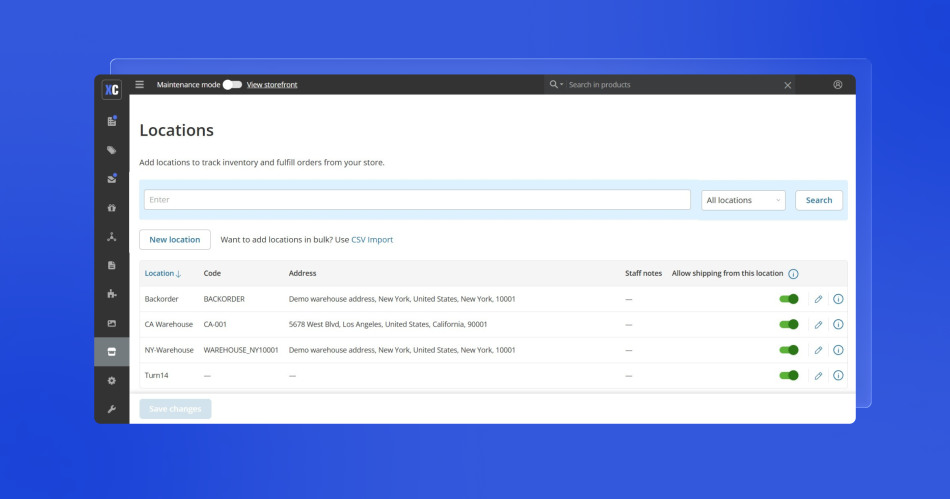

X-Cart was designed to connect to multiple fulfillment centers and supplier warehouses. Its order routing system lets you manage inventory from all these multiple sources. You can use X-Cart’s automated order routing to route orders to your own fulfillment center or send them directly to a distributor like Turn 14 Distribution or Meyer Distributing.

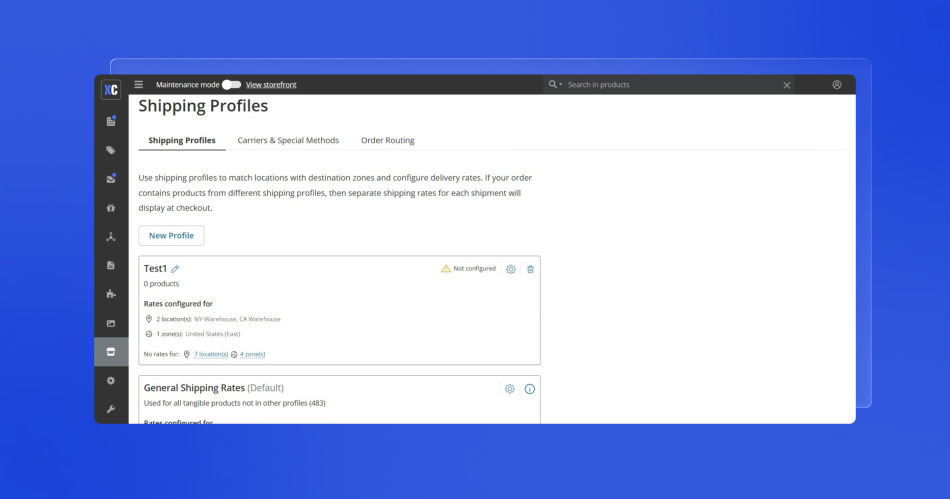

Intelligent Order Routing & Shipping Profiles

X-Cart’s platform features Intelligent Order Routing, which is not a marketing term. It is the routing process we just described. You can create shipping profiles and routing rules that determine how order routes are chosen. You can set priorities to minimize split shipments, control shipping by location, and track your inventory from a centralized dashboard.

Real-Time Stock & Location Tracking

The smart order routing in X-Cart works because it is tied to your inventory levels. The platform gives you a centralized view to Track Inventory Per Location. The real-time data feeds the order routing system, so it always makes decisions based on what you actually have in stock and where that stock is.

For an auto parts seller, this native order routing capability is a true competitive edge. It means your order processing is not a manual, 10-step process. It is a single, automated process. The customer clicks Buy, and X-Cart’s order routing system handles the rest.

Payoff: Why a Great Order Routing Process Matters

Finetuning your order routing process is not a small tweak, but a fundamental shift in your business.

Massively Reduce Shipping Costs

This is the clearest win. By always shipping from the nearest distribution center with stock, you stop wasting money sending heavy parts across the country. This has a direct impact on your bottom line.

Boost Delivery Speed and Customer Satisfaction

You have more chances to win repeat business. Smart order routing means faster order processing and shorter delivery times. You meet customer demands for speed and build trust.

Improve Operational Efficiency

Think of the hours your team wastes assigning orders or figuring out shipping costs. Automatic order routing gives those hours back. Your order management becomes smoother, allowing your team to focus on growth, not fulfilling orders.

Smarter Inventory Control

A good order routing system gives you a clear view of your inventory. You see what sells, where it sells from, and when you need to re-stock. You can improve your demand planning and ensure your available stock is always in the right fulfillment center.

Switch to Automated Order Routing This Year

In the complex world of aftermarket auto parts eCommerce, your order routing is your engine. A simple, one-warehouse routing process is like a 4-cylinder in a business that needs a V8.

To manage multiple fulfillment centers, complex shipping costs, and high customer demands, you need an automated order routing system to connect your customers with your inventory in the cheapest and fastest way possible.

X-Cart provides this smart order routing as a core feature, designed for the challenges of the auto parts market. It is the tool that allows you to stop worrying about costs and start focusing on your competitive edge!

Need a platform for selling auto parts that understands where your orders come from?

About the author